Recently IACS has introduced a new requirement (UR E24) for ships with electric propulsion, regarding the monitoring and recording of harmonic voltage distortion levels on the vessel’s electrical power system. The purpose is to provide early detection in the deterioration of capacitors and other components within both passive and active harmonic filters installed on these vessels.

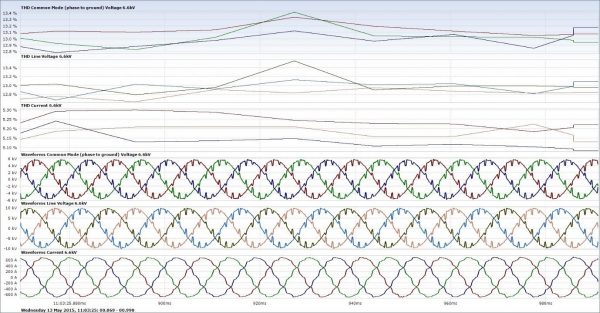

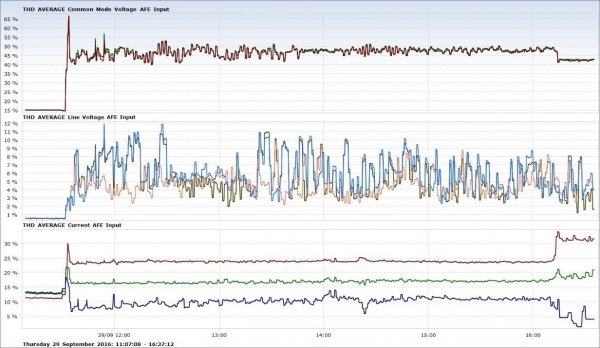

There are other vessels however with multi-pulse main electric propulsion and other large drives where the Uthd (total harmonic voltage distortion) is excessive (as illustrated) and considerably above the marine classification societies limits which, for now, is being ignored by those same marine classification societies and IACS.

Note : Excessive Uthd may result in operational issues with some equipment and be non -compliant with marine classification society rules. At present there is no official requirement for continuous harmonic voltage or power quality monitoring for vessels with electrical propulsion unless they have passive or harmonic filters. However, for such vessels, harmonic and PQ monitoring is highly recommended.

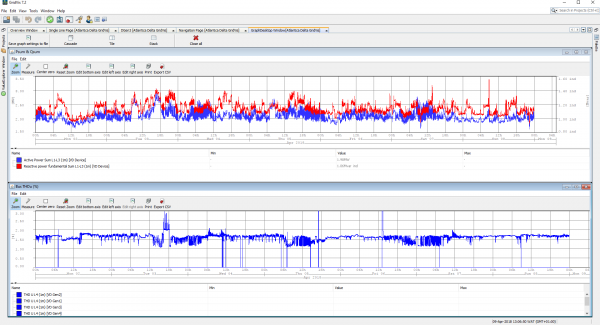

The rationale for continuous power quality monitoring is clear. As well as satisfying current and future regulatory requirements with respect to harmonic voltage distortion levels, continuous monitoring can ensure that any signs of degradation in power quality are recognized timeously and remedial action taken to resolve matters before equipment is adversely affected leading to disruption, equipment failure or worse. Any ‘events’ leading up to, for example, a total blackout of power are captured and used to assist in any investigations as to the cause.

To address the diverse requirements Harmonic Solutions Marine offers two variants of PQGuard which offer continuous harmonics and power quality monitoring.

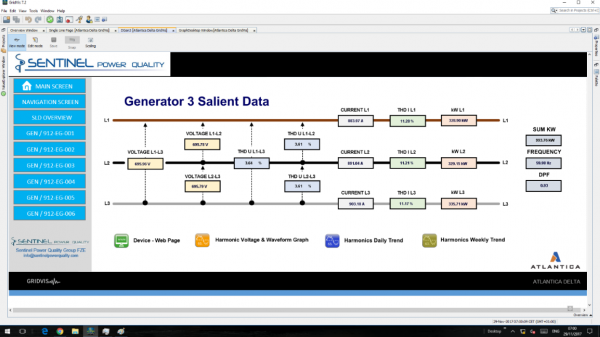

PQGuard 605 – A conventional type of panel or switchboard mounted power and PQ analyser which measures to the 63rd harmonic. Applications include monitoring of single unit or multiple unit PQ monitoring on switchboards, generators and significant non-linear loads.

PQGuard 4430 – A very advanced cycle by cycle recorder which records and captures every single cycle of voltage and current, almost 10,000 parameters and harmonics up to the 512th. These are applied in applications where significantly more PQ data is required and where deep analysis into for, example, the cause of a fault is crucial.

PQGuard 605 – A conventional type analyser/recorder

- Voltages (line and phase voltages)

- Total harmonic voltage distortion both including Uthd (line voltages) and Vthd (phase voltages) up the 63rd order

- Currents (A)

- Current distortion (Ithd)

- Frequency (Hz)

- Energy – kW, kVA, kVAr

- Displacement power factor (DPF) and true power factor (TPF)

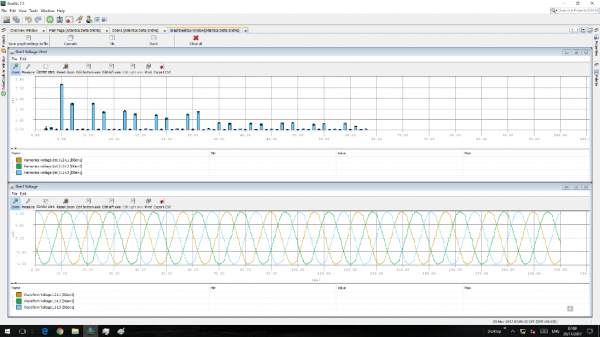

- Harmonic voltages and currents (tables and harmonic spectrums to or 63rd order)

- Flicker (Pst)

- Temperature (if PT 100s connected)

PQGuard, as a local/remote power quality monitoring system has powerful features :

- Full set of trend recordings with date/time playback. PQGuard 605 provides magnification of parameter display to assist with analysis. The trend recording parameters are updated every second. The accuracy is based on the sampling rate.

- Adjustable event recording (e.g. “BKR 1 trip”) with two cycles before and after the event with playback. The limit values of each PQ parameter can be set and alarms initiated if required. On some more advanced monitors, emails can be sent to programmed address(s) to advise and event has occurred.

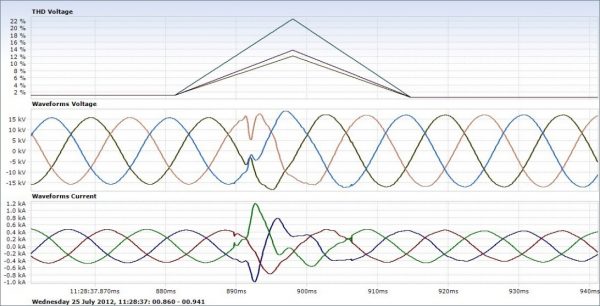

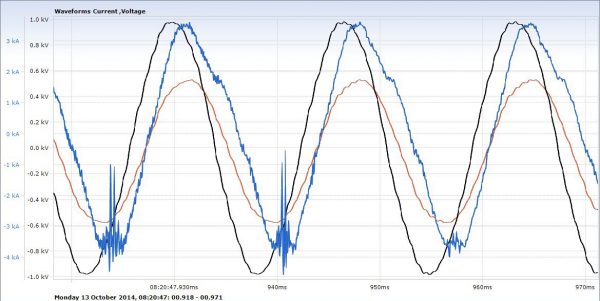

- Waveforms of voltage and current for trouble shooting or monitoring. PQGuard can provide magnification of waveforms and spectrums to assist real time analysis.

- Harmonic voltage and current spectrums at point of connection to 63rd harmonic. PQGuard allows for waveform magnification for analysis purposes.

- If additional I/O installed, MCCBs and other equipment can be monitored (on some units).

The complete system, including Industrial computers and servers are available from Harmonic Solutions Marine.

One PQGuard 605 can be connected to the vessel’s switchboard to satisfy the requirements of marine classification societies under IACS (UR E24) with regard to continuous PQ monitoring (similar to that outlined in the PQGuard 4430 section).

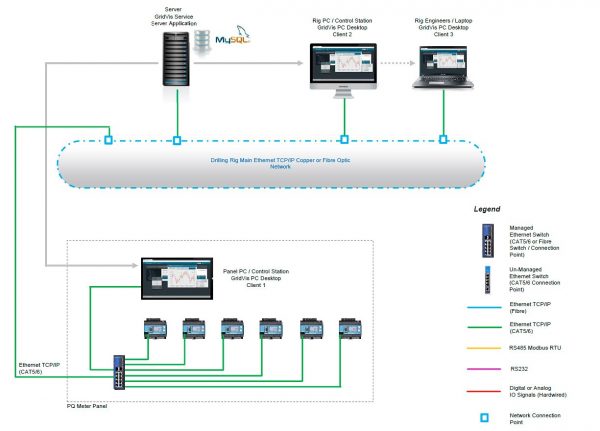

Alternatively, PQGuard 605 can be installed on each generator, as illustrated previously, for optimum PQ monitoring. An example of the overall system, based on this installation on a drilling tender, can be seen.

PQGuard 4430 – Advanced cycle by cycle recorder

PQGuard 4430 is an advanced ‘cycle by cycle’ power quality recorder (not analyser), which when combined with dedicated power quality analytic software, provides unarguably the world’s finest harmonics, power quality and events monitoring system.

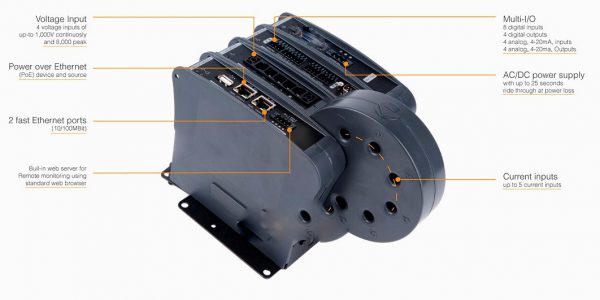

The PQGuard 4430 recorder can accommodate current signals up to 5A per phase from conventional current transformer or via flexible Rogowski coils.

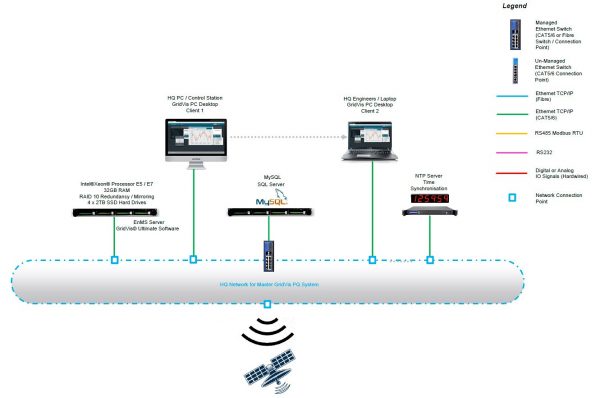

The complete system, including industrial computers and servers are available from Harmonic Solutions Marine.

The photograph shows the optional ‘multi I/O extension module installed. This I/O module includes analogue and digital I/O, in addition to relay outputs. This allows us to tailor the I/O to your precise application requirements. With the PQGuard 4430, the operation, reliability and temperature of generators, transformers, circuit breakers and critical equipment can be monitored.

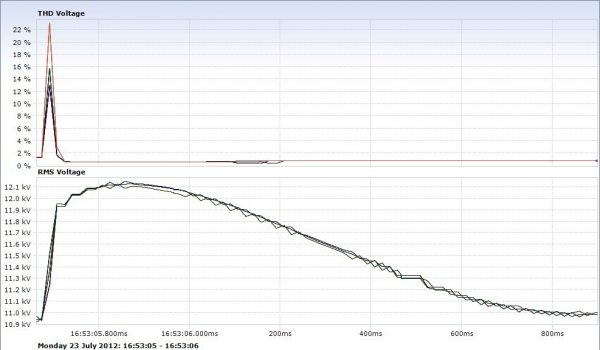

The PQGuard 4430 samples 1024 points per cycle and continuously records every single cycle for up to one year. With the PQGuard 4430 it is simple to go from recordings of months to an event of milli-seconds or micro-seconds with a mouse.

Every single cycle of voltage and current are recorded plus almost 10,000 power and PQ parameters. Harmonic voltages to the 512th and harmonic currents up to the 258th are captured.

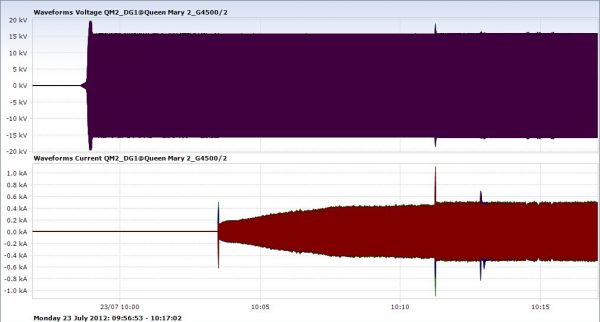

No event is missed. The example illustrated shows an event on a vessel. The event illustrated was <2.7ms long (0.162 of a cycle).

Additional features of PQGuard 4430 :

- Sampling : 1024 samples/cycle

- Harmonics & Interharmonics : Up to 512th voltage and 258th current

- Internal memory : 16GB

- Transient detection : 19.5/16.3μs (50Hz/60Hz)

- Ethernet ports : 2

- Ride through power loss : Up to 25 secs

- Voltage channels : 4 off plus ground, 1000V rms continuously (8kV peak)

- Current channels : Up to 5 off, up to 5A (50A peak)

- Fundamental frequency : 42.5hZ to 69Hz

- Power supply : 110-260VAC and 100-300VDC, 48 VDC auxiliary

- Operational ambient : -20 deg to 70 deg C

In addition to recording every single cycle of voltage and current, almost 10,000 power and power quality parameters are automatically captured and stored via PQZip, a patented process which compresses the data over 1000 times (all these parameters can be fully analysed and compared to others during investigations). The data is de-compressed and displayed to permit analysis or used to provide manual and automatically produced standard or customised reports.

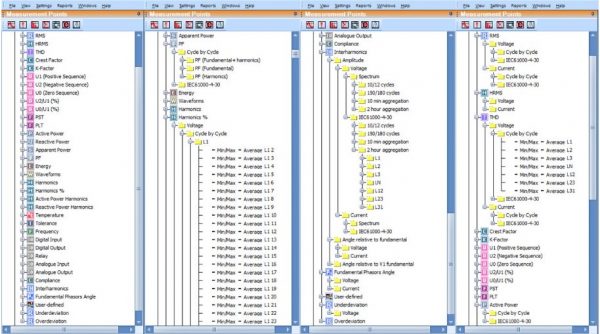

Samples of typical parameter trees, using InvestigatorTM, software is shown. Depending on specific reporting and other requirements, alternative software can be utilised.

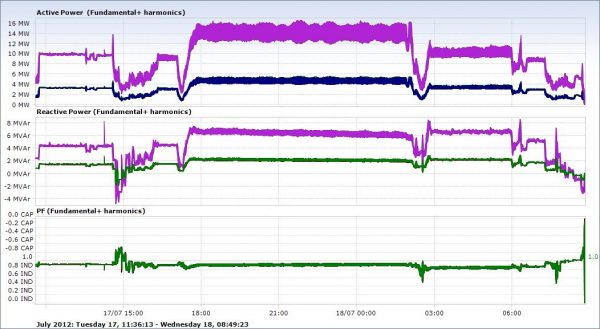

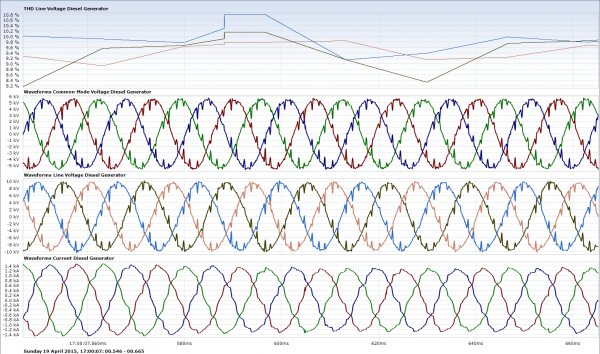

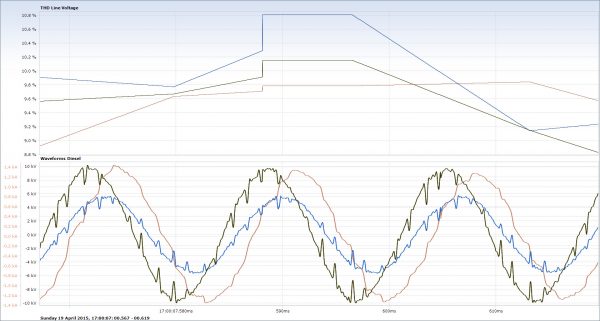

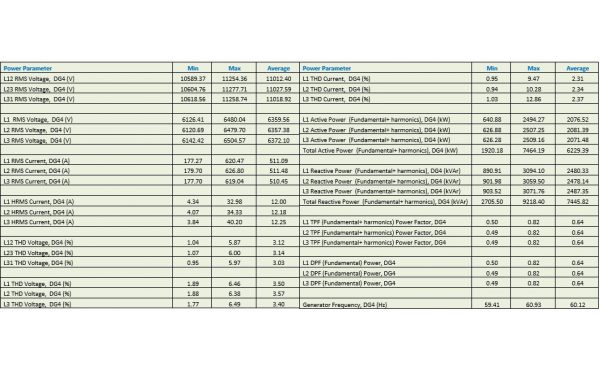

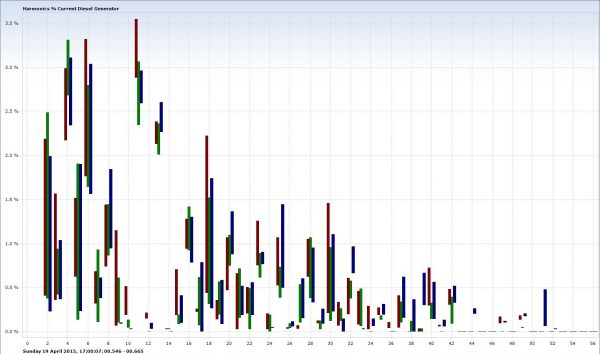

A selection of the types of measurements captured on vessels follows :

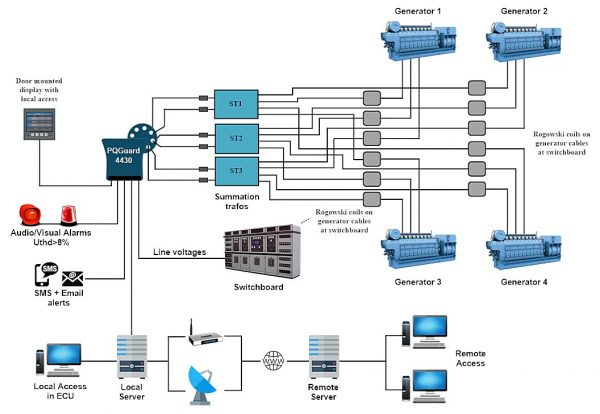

PQGuard 4430 can be installed on each generator, if required, for optimum PQ monitoring. Alternatively, it can be connected to the vessel’s switchboard (as shown) to satisfy the requirements of marine classification societies under IACS (UR E24) with regard to continuous PQ monitoring for vessels with electric propulsion.

The simplified illustration depicts a typical single PQGuard 4430 application. Note that the generator currents are summed and fed into the unit. Conventional CTs or Rogowski coils (flexible current transducers) can be used.

Visual and audible alarms are triggered, for example, in the event of the Uthd >8% being exceeded. All events are logged and can also be communicated by email and SMS. The PQGuard unit is usually installed in the main switchboard room and communicates with a dedicated local server (usually a desktop computer) in the Engine Control Room (ECR).

As can be seen there is also the capability to being able to monitor the PQ remotely should a suitable internet connection be available. This may be at the company Head Quarters or at a third-party company’s office, directly responsible for monitoring the vessels PQ.

Contract PQ Monitoring

Whatever the type of PQGuard system you wish installed on your vessel, Harmonic Solutions Marine, can offer contract PQ monitoring. Let us take the full technical responsibility from your company by continuously monitoring, analysing and reporting on your vessel’s harmonics and power quality, whether a cruise liner to an offshore support vessel.

This service can also entail detailed annual PQ audits, if applicable, including the systems downstream where the normal continuous PQ monitoring does not apply.

Note : Harmonics above the 50th

Contrary to the impression given in most standards and rules of marine classification societies, harmonics do not cease at the 50th order. Indeed, there is officially a new class of harmonics called “supra-harmonics” in the range 4kHz to 150kHz.

The limit for harmonics at the 50th may be convenient for compliance with rules and standards but can jeopardise the safety and operational integrity of the vessel as the complete ‘harmonic and PQ picture’ is hidden when using conventional harmonic and PQ analysers which measure to the 50th (or 63rd).

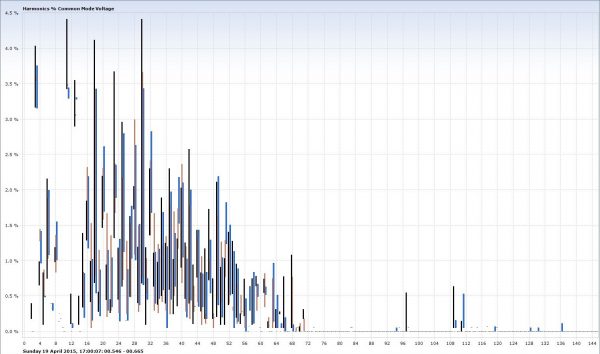

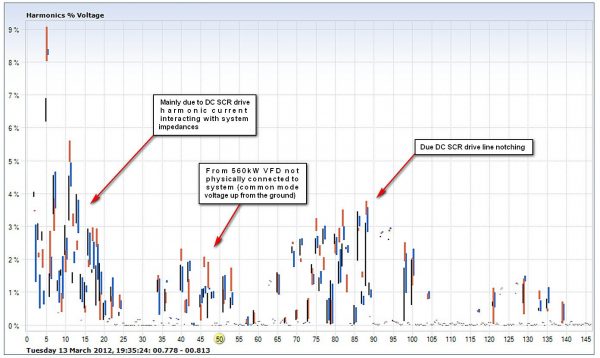

Illustrated below is an example from a vessel with a mix of large DC SCR drives and VFDs. The 50th harmonic limit has been highlighted on the axis. Note that the line voltage extends to the 141st order, but in fact, there are essentially three discrete spectrums;

- One spectrum to around 25th order due to the harmonic currents being drawn from the supply by the large DC drives.

- Another spectrum (~33rd to 53rd order) due to a 560kW VFD, not physically connected to the power system (it had its own generator). This is the VFD’s common mode voltage appeared on system busbars via the ground (hull) connection.

- Finally, the high frequency voltage harmonics (57th to 104th) due to the DC SCR drive line notching.

It should be obvious from this example that anyone attempting to trouble-shoot harmonics, PQ and EMC (i.e. common mode) problems whilst looking up to the 50th harmonic and may be unsuccessful in their endeavours.

It should be noted that Harmonic Solutions Marine has been measuring harmonics to the 512th harmonic since 2010. Some examples of those measurements can be seen in the following section. The PQGuard 4430 also has the capability to measure to the 512th harmonic. PQGuard 605 measures to the 63rd order at this time.